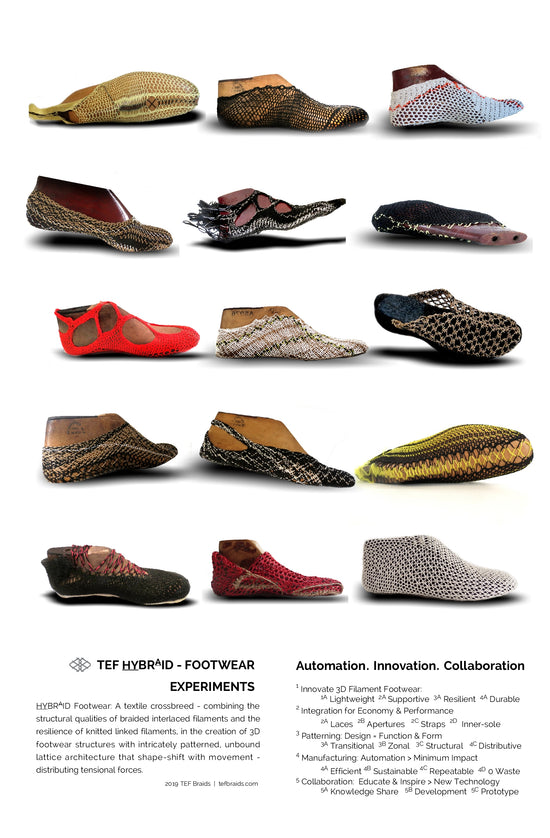

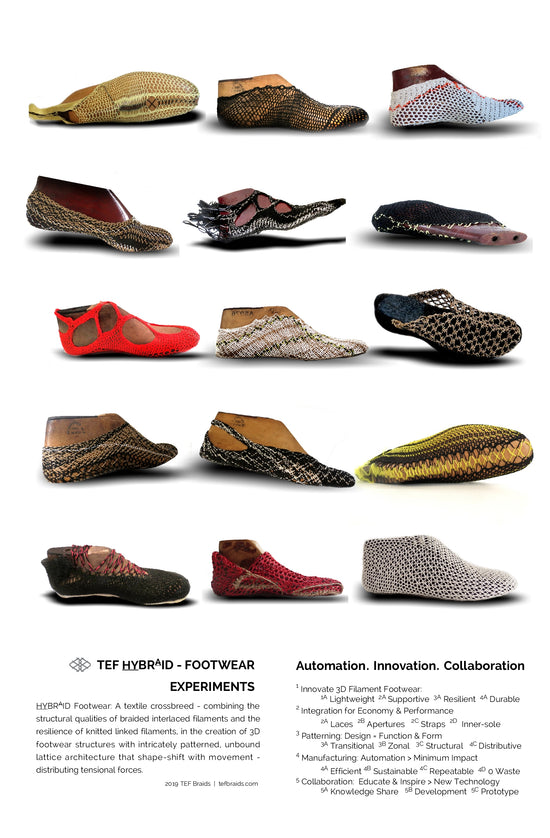

These minimalist, high performance, adaptable structures are the future of footwear.

Check out our ongoing experiments and be in touch if you are inspired.

-

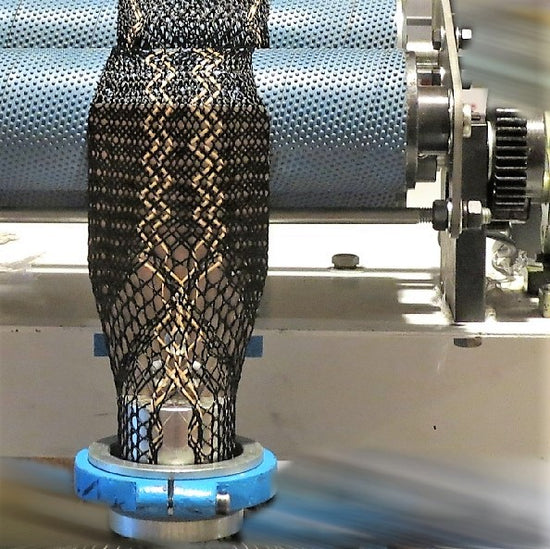

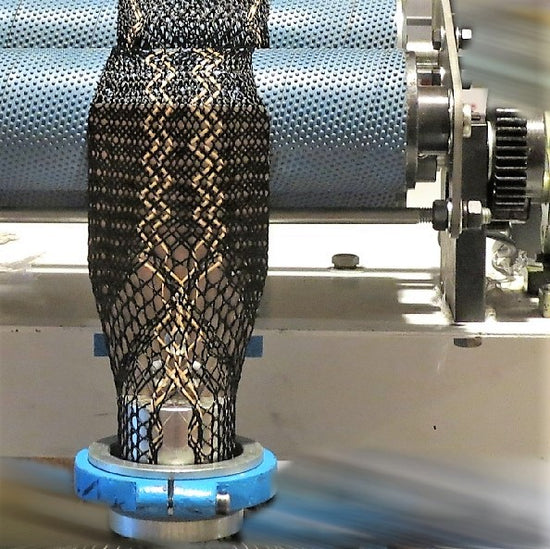

Our companies are TEF Braids and Tensengral. We use programmable braiding machines with a patterning technology we invented to create functional fabrics and products.

-

We practice the art with heritage jacquard circular lace braiding machines that have been updated with CAD and electronic controls.

-

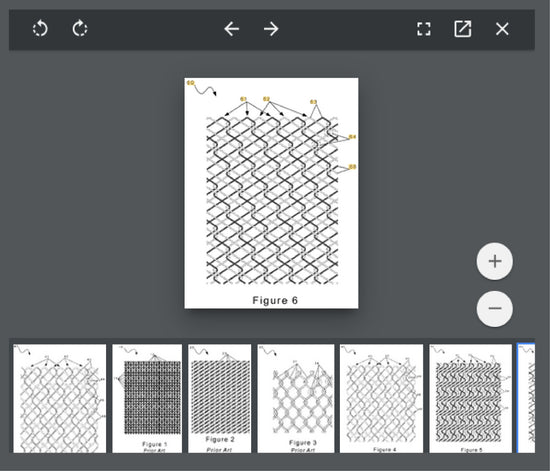

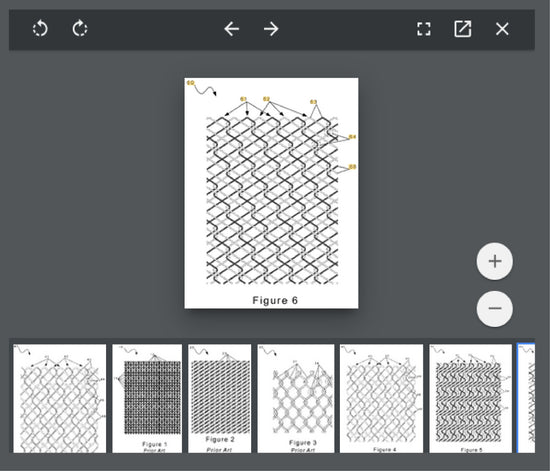

We've patented fabrics to use with the machines that expand the scope and definition of both a braid and lace.

Plexus of filaments with linked members

Patterned plexus of filaments and articles made from patterned filaments.

-

The braiding and patterning process enable virtually waste-free, efficient manufacturing for many different products using scalable, somewhat easy to learn processes.

-

The footwear manufacturing process is efficient since we can make the fabric for an upper, sized correctly, in one step - including functional laces.

-

We can use virtually any thread or yarn combination. - We can even impregnate yarns and make footwear with a "skin and bones" bio-mimicry like performance.

-

Just as valuable as the machine that makes the fabric is the way the yarns of the fabric are oriented, meaning how and when they link and interlace. These unique patterns are described in our patents.

-

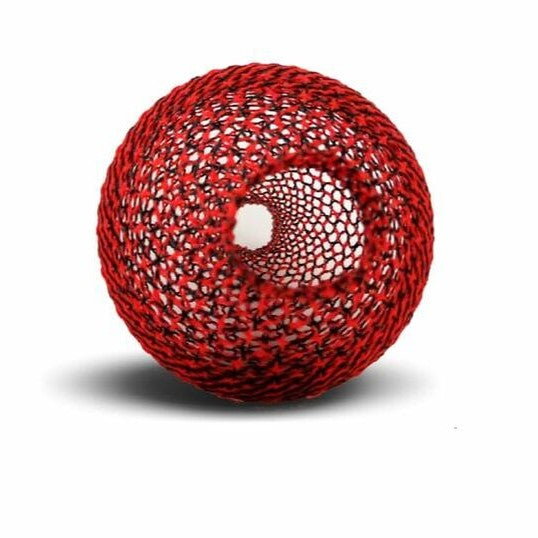

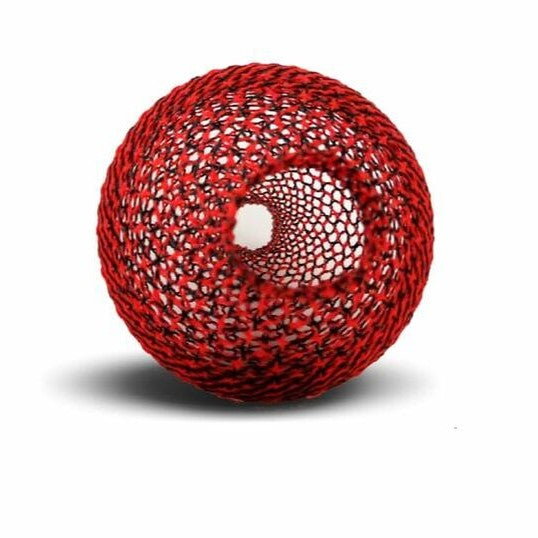

The second fabric we patented made with ALX, family of patterns, unifies groups of spiraling filaments through links that, when locked out, naturally and magically shape-shift to distribute tension. We've tested these fabrics with our AMBI bralette. "Super comfortable, almost invisible" is the response.

-

The result of this behavior is increased comfort, longevity and a new kind of "fluid" support created by subtly shifting filaments.

-

The tensioned, non-elasticized fabric has a way of "grabbing and holding" a foot along readily morphed ”structural” lines. The fluid grab and hold is what makes the fabric so good. No more slipping, buckling or rubbing.

-

There's also a micro-massage effect, we think, due to the rolling of the fibers as they adjust to distribute tensions throughout the unified structure -- a really nice thing for underwear.

-

Designs options are vast. Our newest experiments involve a footwear upper comprising one piece of patterned material having inner and outer layers that are partially attached in a torus shape.

-

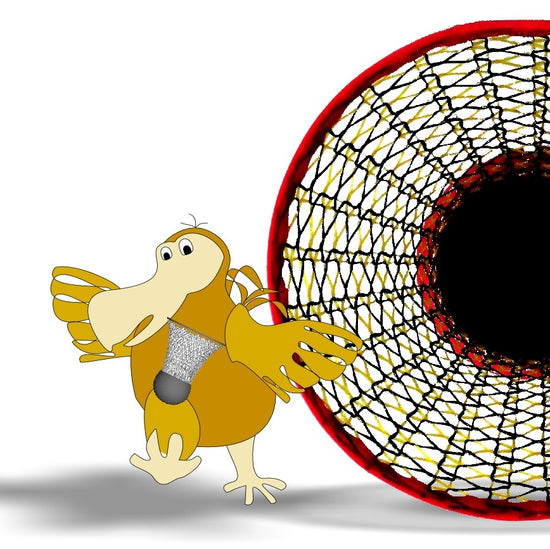

Decades ago we began this braiding innovation when un-successfully seeking a stable, unbound mesh material that was impact resistant and conformal, for a sport product called Birdball.

-

We never would have guessed that a good bit of our life would be spent developing these fabrics, conceiving of products wherein they would be useful and learning the "ins and outs" of these century old machines - crazy indeed!

-

You never know who else might be looking for this sort of material or who we might inspire to think outside the box for foootwear design.

-

Contact

ContactMaybe we'll make the world's next best shoe together. We love to talk about programmable braiding so, be in touch to learn more.