Sustainability

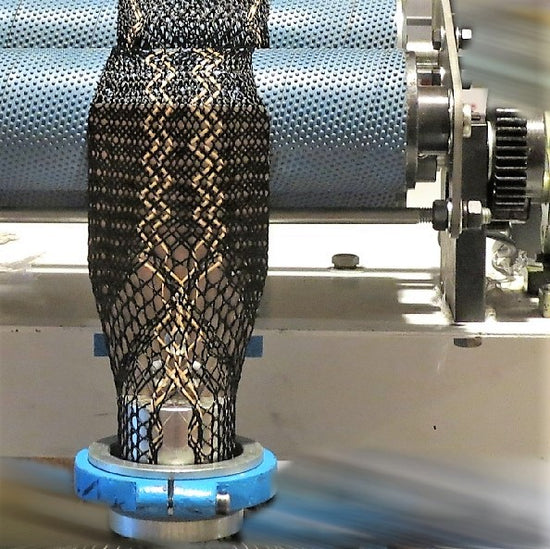

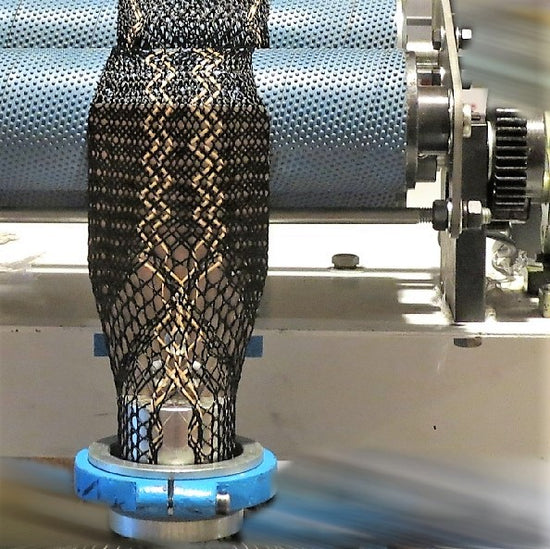

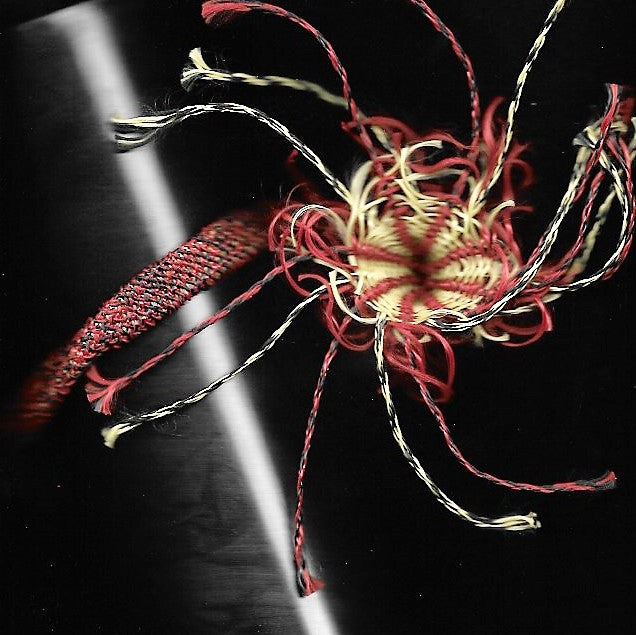

Braided patterned material as structural, fluid textile forms have enormous unexplored implications for many textile categories. We are incorporating this technology to build performance into fabrics to minimize product finishing, materials, and waste. Our technology makes possible on-demand manufacturing, a viable solution to overproduction and pollution.

-

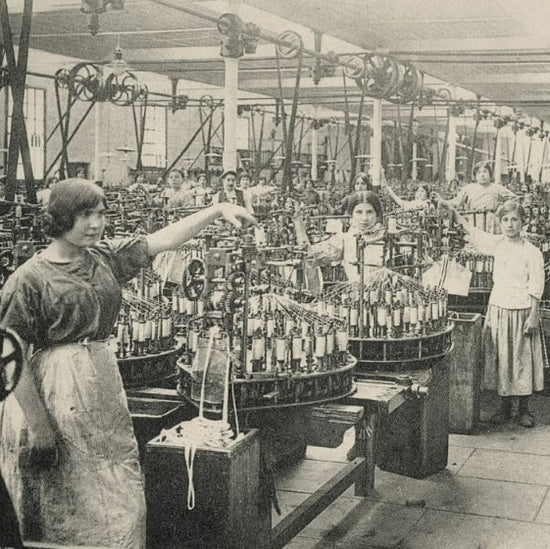

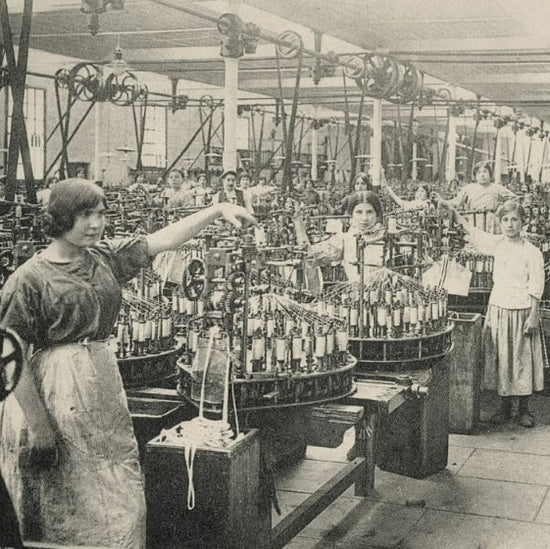

The lace braiding machines of the early 19th century were expressly invented to mimic the motion of a bobbin lace maker's hands. These early machines used punch cards to control the motion of the spindles.

-

Toward the end of the 19th century refurbished lace making machines were fitted with CAD systems to control the motion of the spindles. This advancement opened the door for creation of new fabrics that merged the structural qualities of a braid with the fluid nature of linked filaments.

-

By repurposing century old machines, an entirely new technology and way of building light, strong and flexible 3D textile structures became accessible to a larger group of producers, designers and manufacturers.

-

Innovation meets sustainability when these machines and new lace making software enable the production of functional fabrics in a virtually zero waste, efficient way.

-

AMBI demonstrates the less is more fundamental principal of sustainable product design by using a minimum amount of resources to create a high performance product.

-

The result of AMBI's innovation is a new fit and feel paradigm that requires fewer resources, as well as a method of manufacture that is more efficient than historic methods of production.

-

Historically bras have been made by stitching multiple pieces of material together. In contrast, AMBI bras are one continuous piece of fabric that is zonally patterned with the aim to provide a fluid support that adapts to a body in motion.

-

Manufacturing efficiency is achieved by reducing production steps through the seamless integration of essential elements such as elasticized straps and band into the single piece of patterned material. This technique eliminates the need for assembly and stitching of individual pieces. Virtually zero waste is achieved through the elimination of fabric scraps that traditionally are the result of cut and sew production methods.

-

Material choices play a large part in a products sustainability. AMBI is made from a blend of USA grown Supima cotton and Tencel™ yarns. Supima is twice as strong as regular cotton, which makes for a longer-lasting product. Tencel™ is made from sustainably harvested eucalyptus wood pulp using recyclable, earth-friendly solvents.

-

No dyes, fabric finishes used on the final product reduces wastewater pollution, creating an end product that is good for you and the planet.

-

AMBI encourages less consumer consumption by way of it's versatile design, having at least two functional and distinct wearing options in one bra.

Old is New - Less is More

Refurbished Repurposed Machines + Fabrics with Function + USA Virtually Zero Waste Efficient Manufacturing + Locally Grown and Sustainably Produced High Quality Fibers + No Dyes + Versatile Product Function + Maximum Efficiency with Minimum Resources = Our Sustainability