We propose to develop and commercialize the first high-performance braided hemp lacrosse mesh, building on TEF Braids’ decade of innovation in programmable braiding

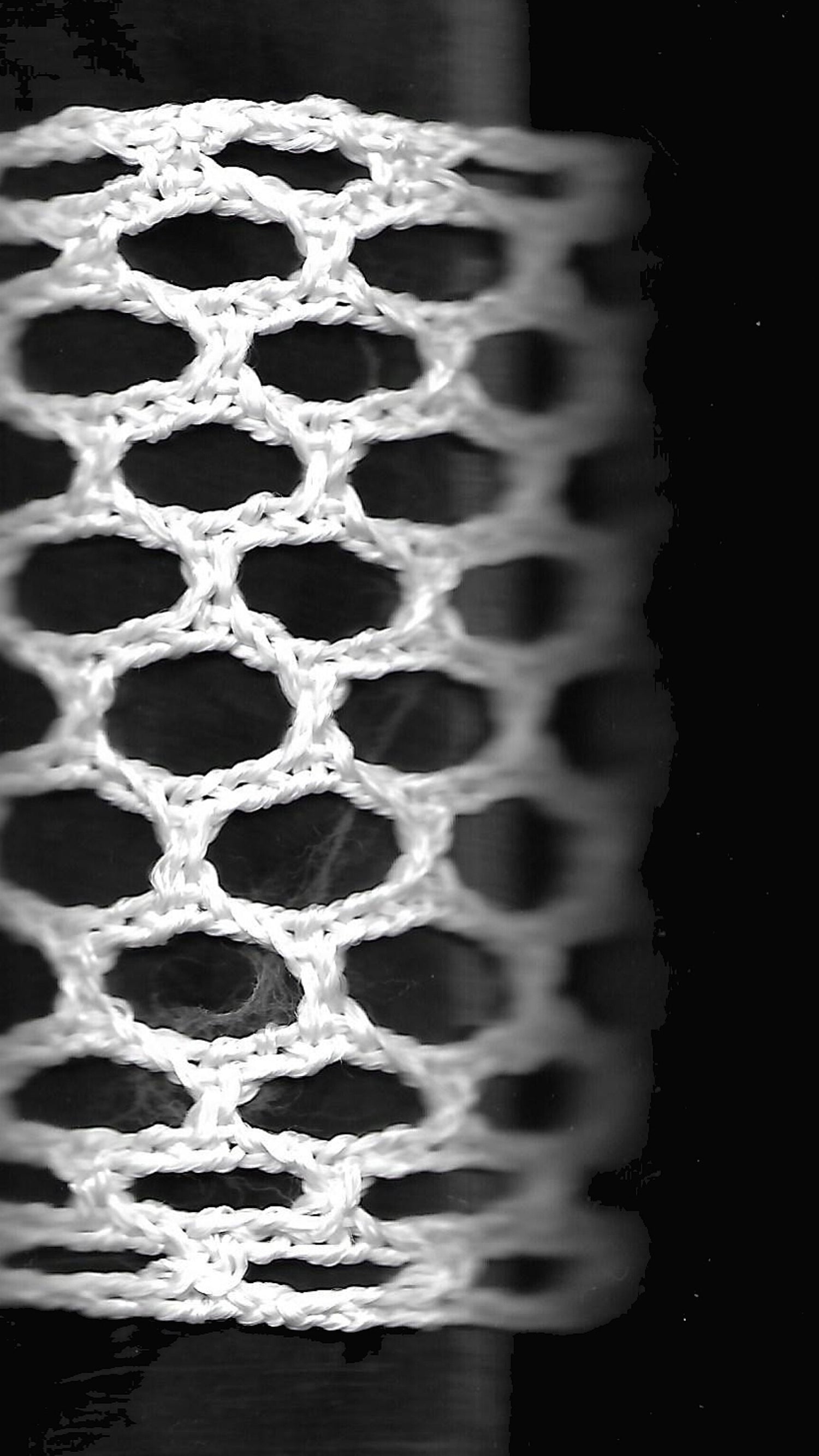

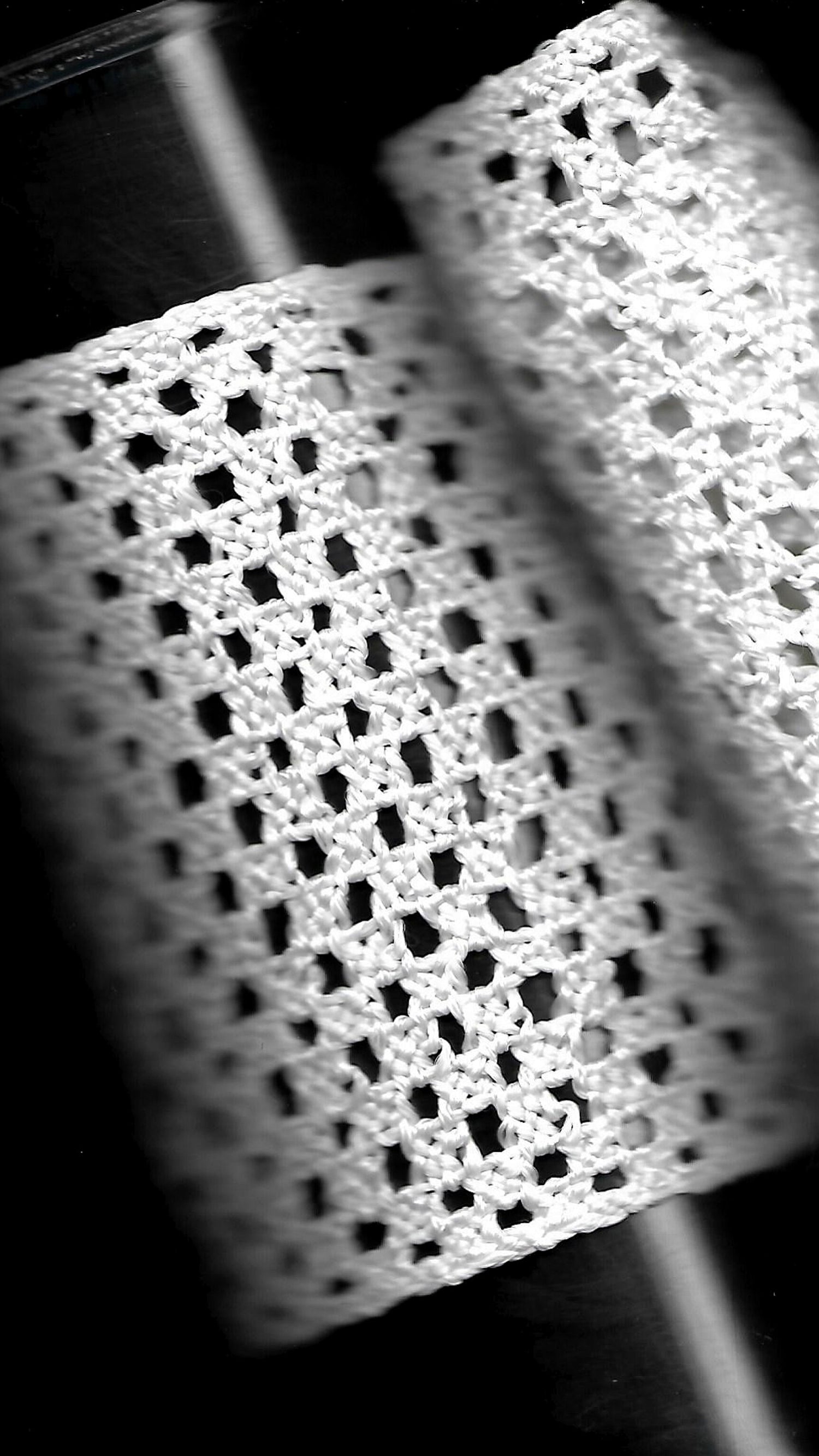

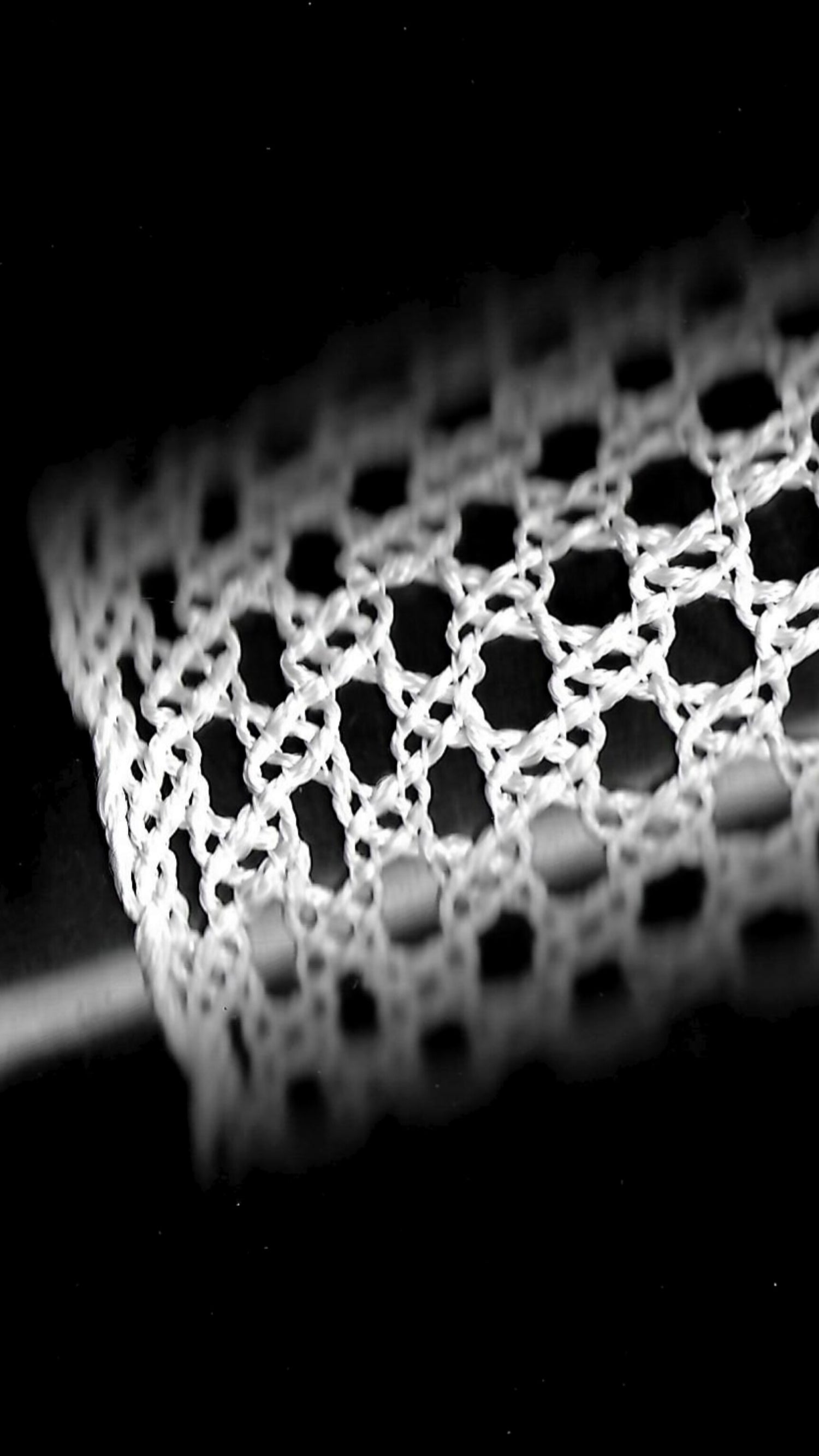

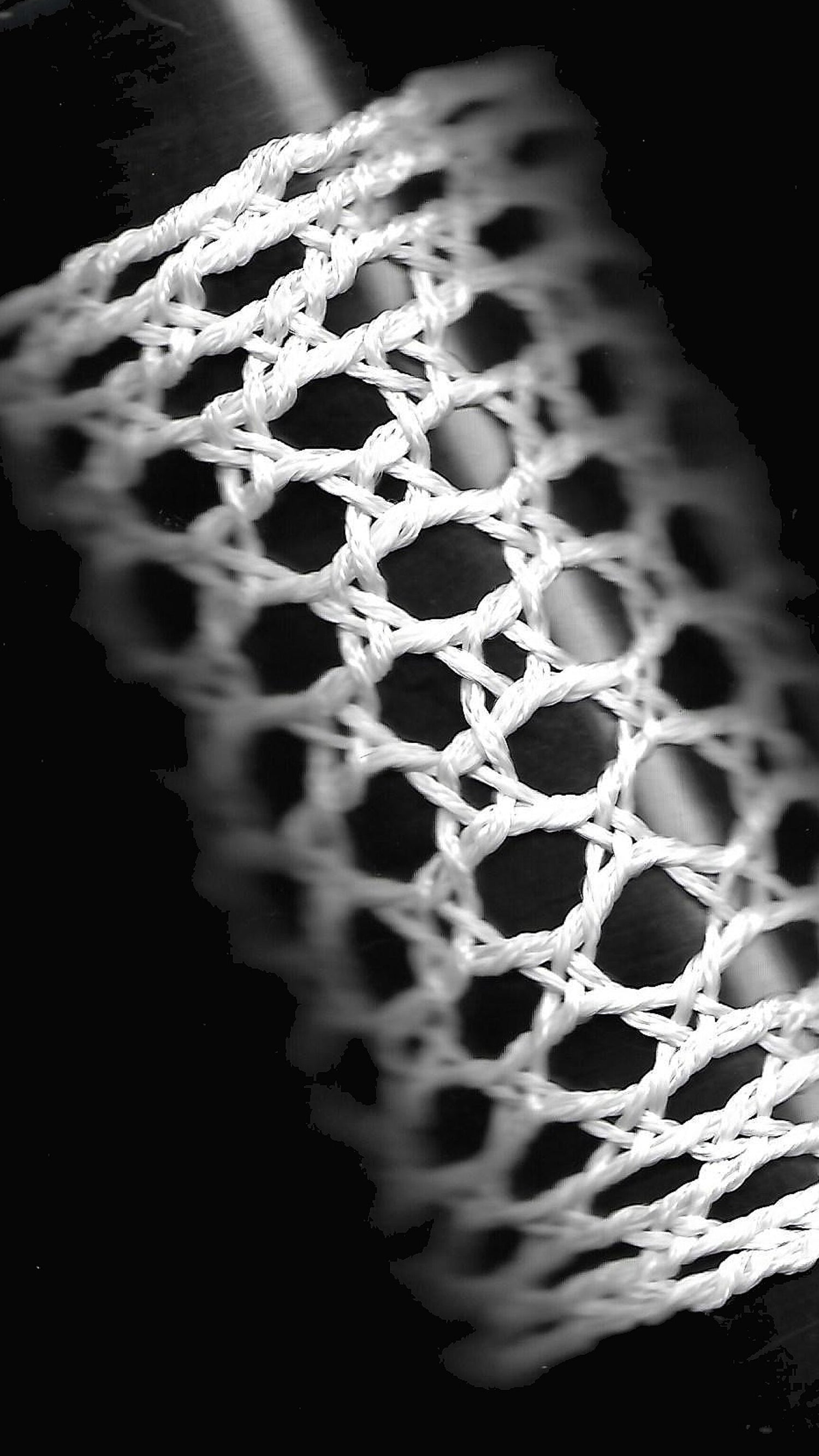

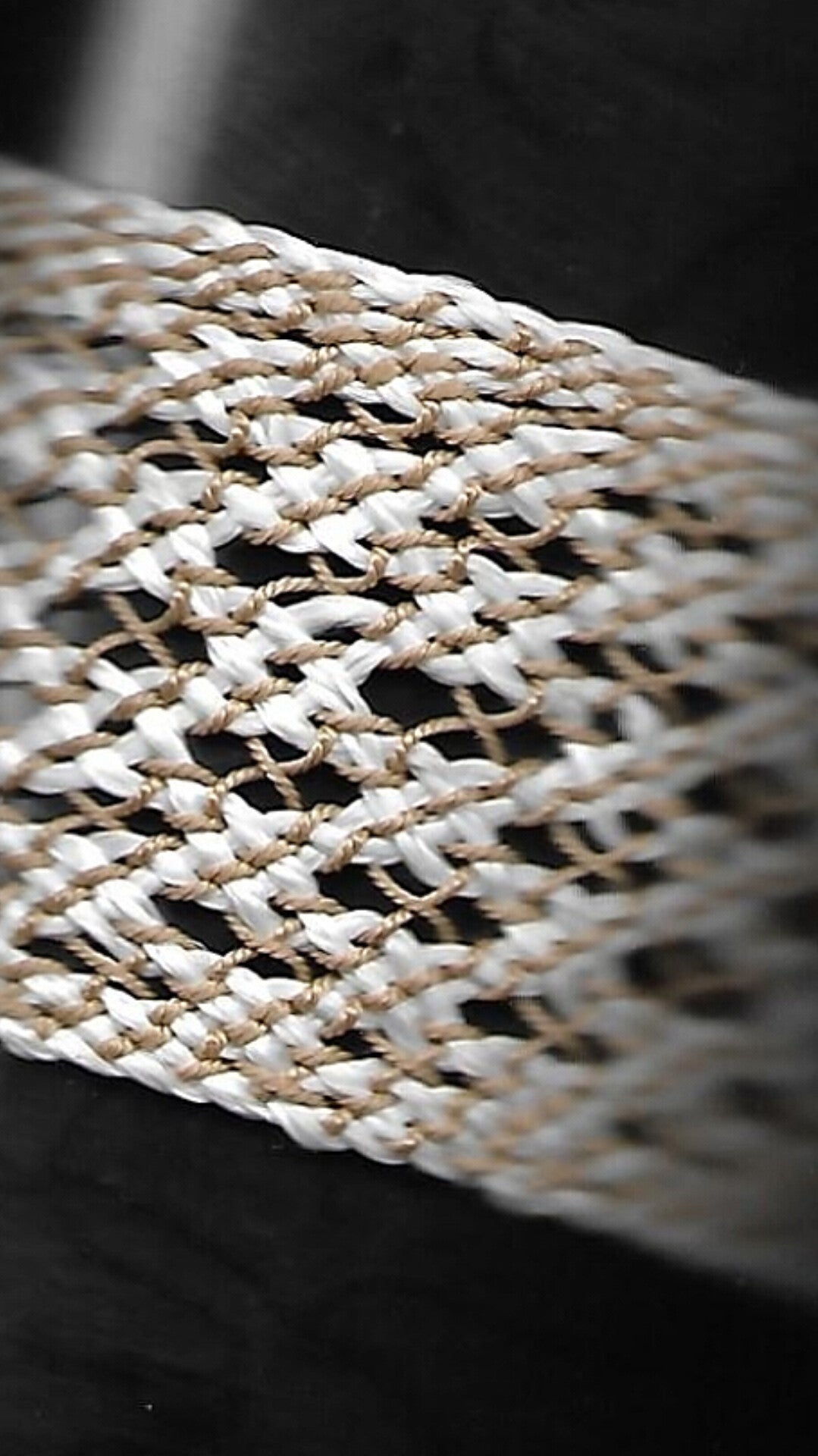

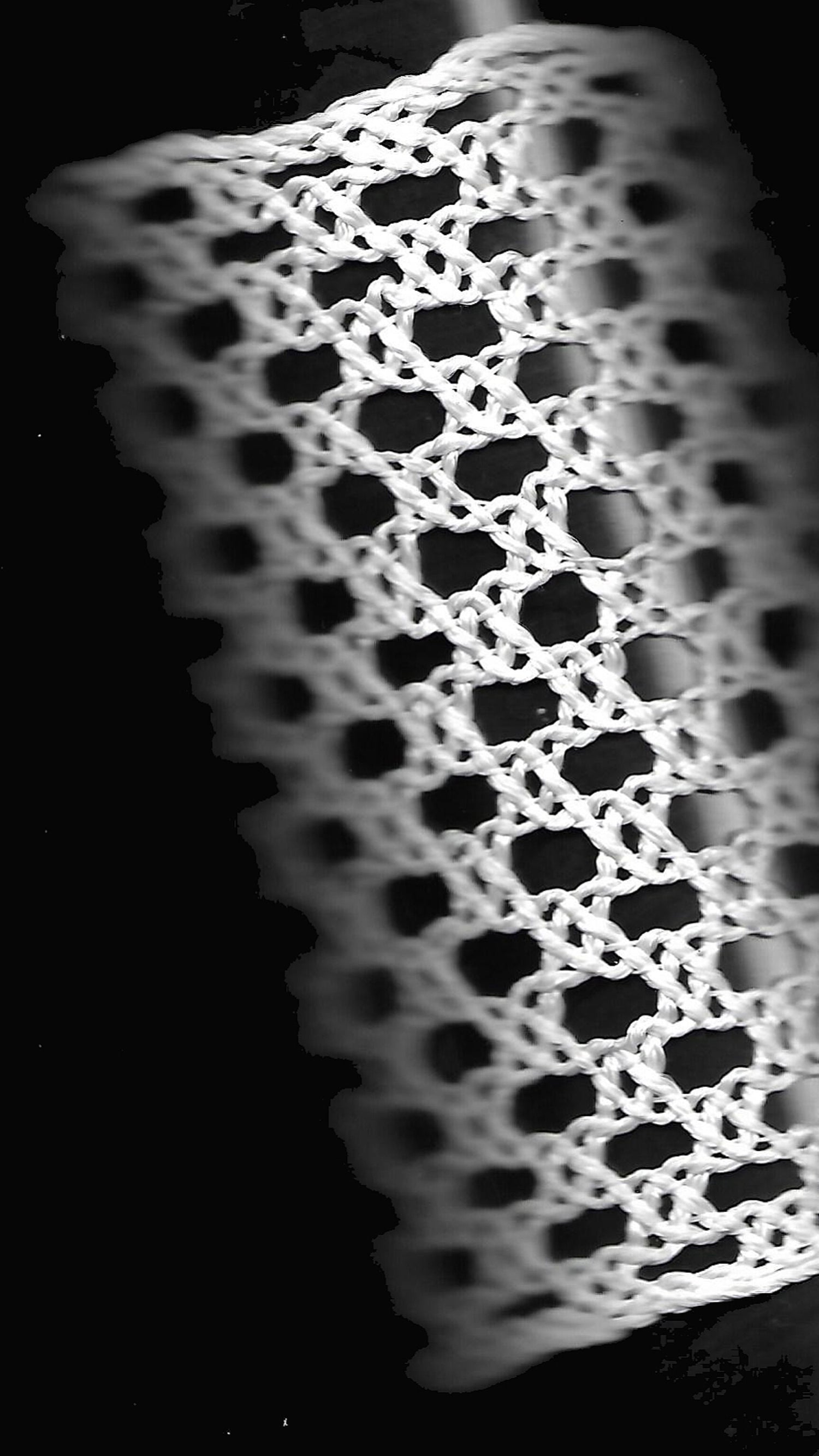

Using our patented XHelX pattern, a self-balancing filament structure that absorbs impact and evenly distributes tension, we will create a sustainable, zero-waste alternative to synthetic mesh. This project will integrate biodegradable hemp yarn, natural finishes, and zoned braid geometry to deliver elite-level responsiveness and durability.

With support from RPI, we will validate mechanical properties, optimize

braiding for lacrosse-specific tension zones, and field-test prototypes

with local athletes.

This collaboration unites TEF Braids’ hands-on manufacturing and design expertise with RPI’s scientific rigor to bring a sustainable, high-performance innovation to market.

We will collaborate with RPI to validate and optimize the performance of

our braided hemp lacrosse mesh through testing, materials analysis, including tensile strength, abrasion resistance, water absorption, and elasticity testing -- comparing our braided hemp mesh against conventional synthetic mesh. We will also explore biodegradable coating enhancements with RPI’s expertise in sustainable polymers and processing.

Braiding Structure for Performance: Zonally patterned and geometrically stable pocket with material advancements to promote whip and hold, designed to maximize shot speed and accuracy.

Water Resistance:

Plant-based wax emulsions (like soy wax, candelilla wax, or beeswax) in light coating. Natural lanolin finish for wool-hemp blend.

Elasticity & Flex Recovery:

Twisted yarns --twisting imparts mechanical elasticity, especially in wool or hemp-wool hybrids.

UV and Mold Resistance:

Hemp is naturally mold-resistant, but for added UV protection: natural tannin-based treatments (e.g., from chestnut or oak extracts) mica or kaolin clay particles for passive UV shielding.

Phase 1: Field Testing with RPI Lacrosse Players

Begin with play-testing our current braided mesh prototypes with lacrosse athletes. Collect performance feedback—focusing on feel, responsiveness, ball control, and consistency under varying field conditions. This user input will guide refinements in braid geometry and material performance.

Phase 2: Hemp Sourcing & Yarn Preparation

Partner with Battenkill Fibers to spin NY-grown hemp into high-performance, braid-ready yarns. Evaluate yarn characteristics such as twist, strength, and elasticity, and their influence on braid structure and durability.

Phase 3: Mechanical Testing & Filament Treatment Exploration

Conduct lab testing to assess tensile strength, flex durability, abrasion resistance, and water absorption. We will also begin exploring different natural filament treatments and finishes—such as waxes or tannins—to enhance performance without compromising biodegradability.

Phase 4: Braid Geometry Optimization

Refine braid pattern for lacrosse-specific tension zoning and dynamic response. Adjust braid density, filament orientation, and edge structure based on both lab and field feedback.

Phase 5: Standards Compliance & Market Preparation

Work in parallel with national lacrosse rulemaking bodies (e.g., USA Lacrosse, NCAA rules committees) to ensure our mesh meets all performance, safety, and dimensional standards for legal play.

Phase 6: Final Prototypes & Commercial Readiness

Integrate all findings into final mesh prototypes ready for production. Prepare technical documentation, possible IP filings, and commercialization materials to bring the product to market as the first high performance, biodegradable lacrosse mesh - Farm to Sport New York!

TEF Braids pioneers fabric and product design innovation by patterning performance directly into textiles through advanced braiding techniques. Utilizing historic Jacquard Circular Lace machines, we create unique fabrics and 3D textile structures featuring zonally targeted performance properties. By seamlessly integrating design and fabrication into a single step, TEF Braids produces efficient, high-performance textiles that redefine sustainable, low-impact manufacturing and functional fabrics.