Describe what your organization/company does:

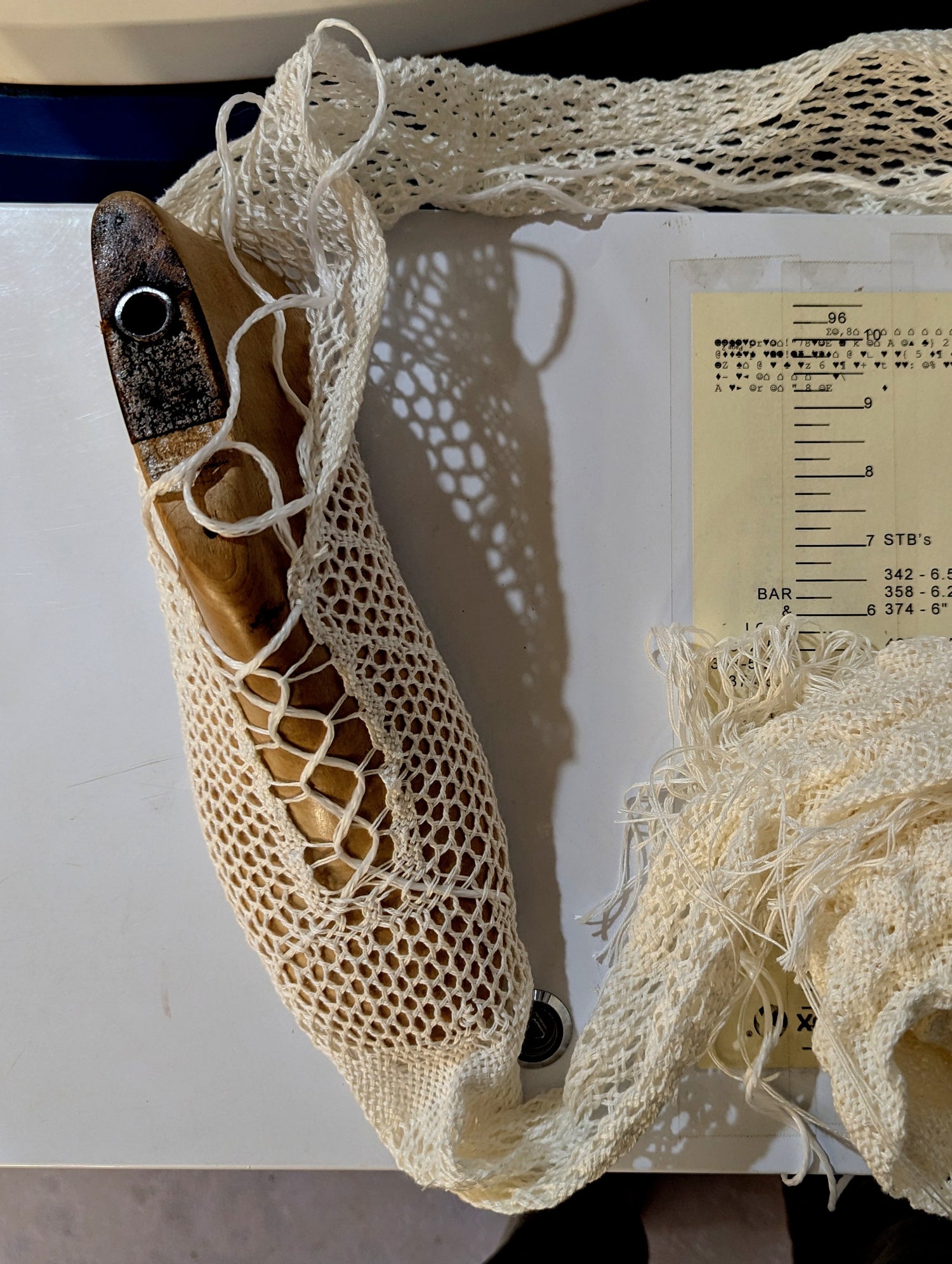

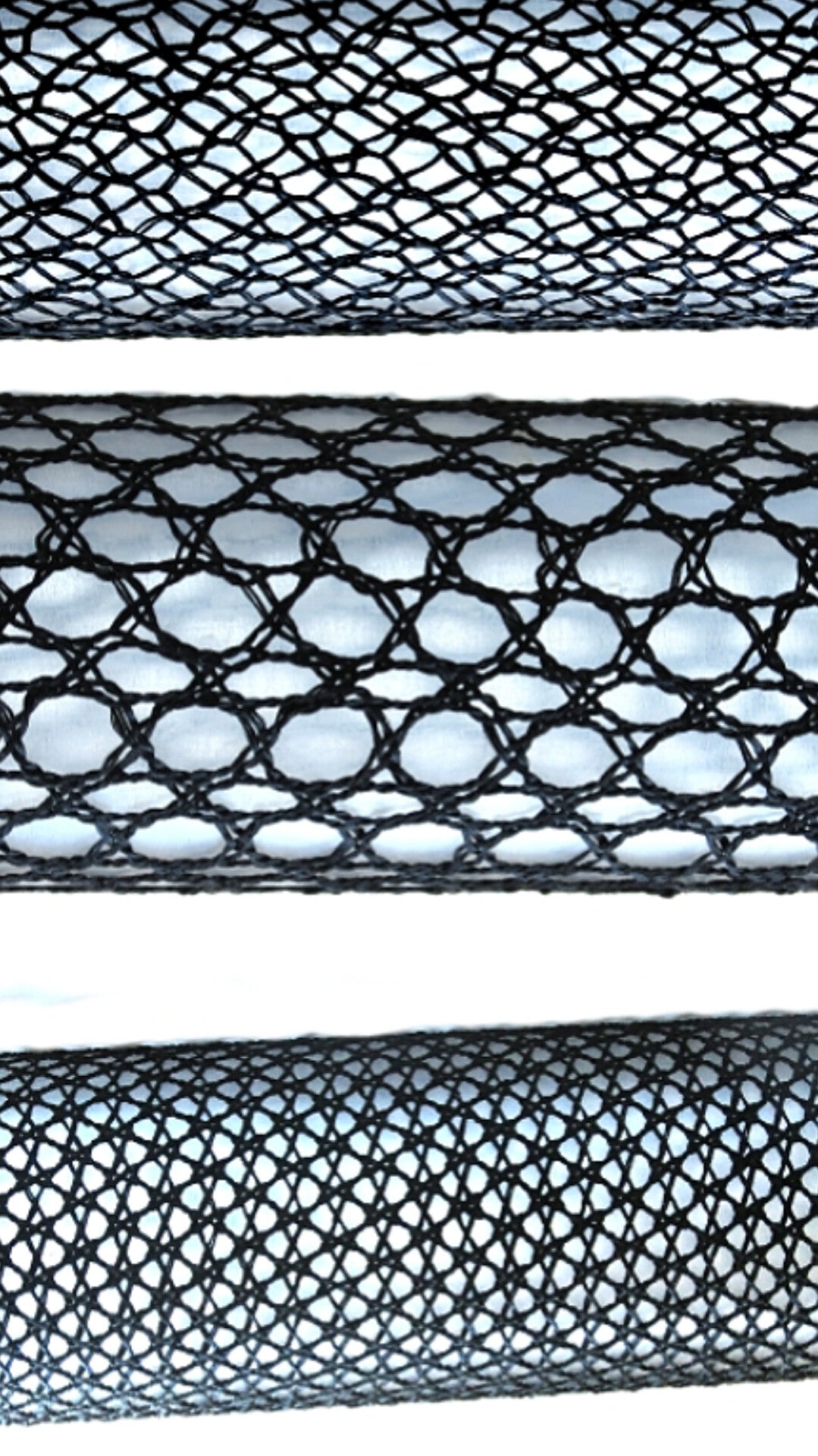

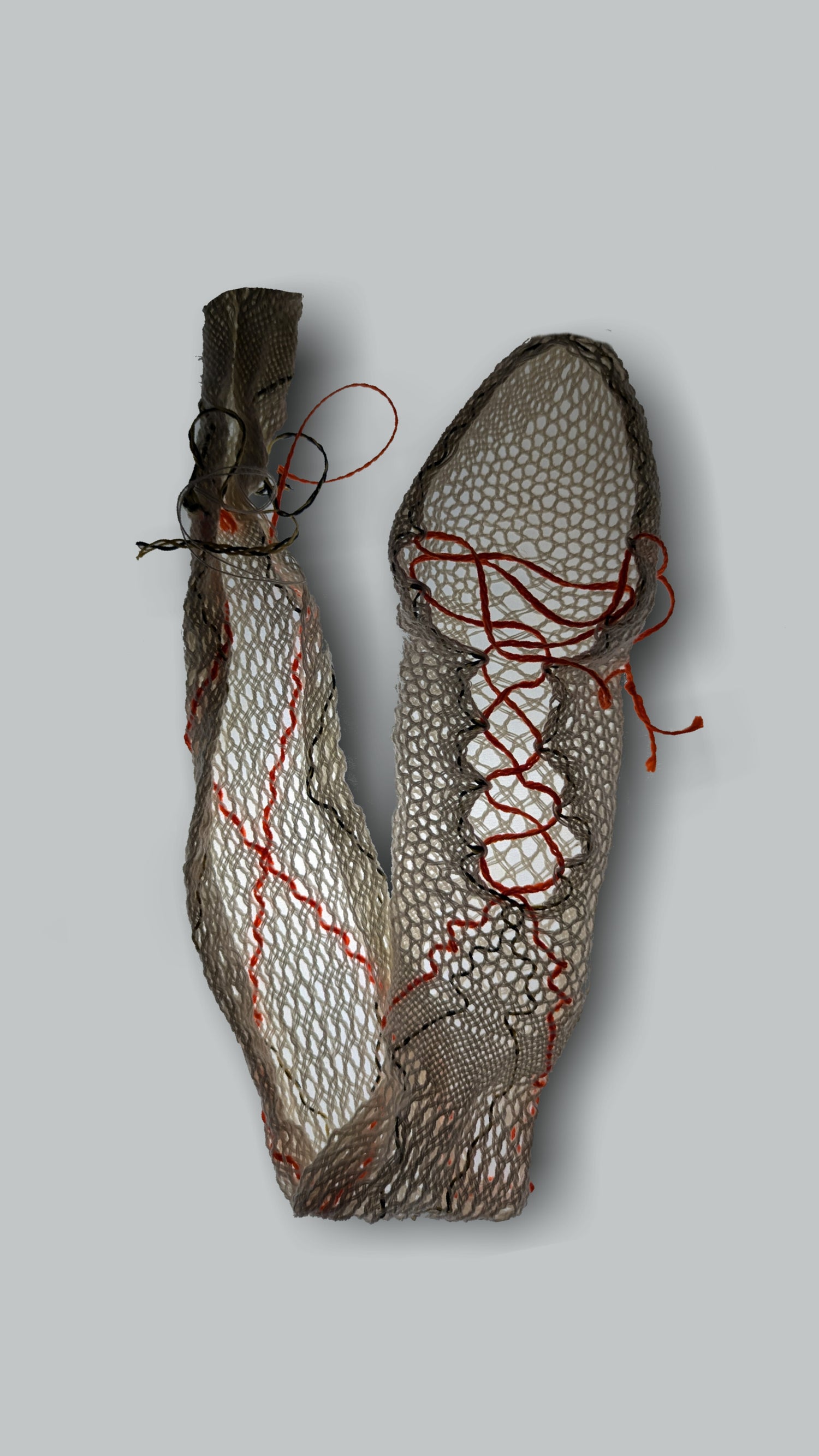

TEF Braids pioneers fabric and product design innovation by patterning performance directly into textiles through advanced braiding techniques. Utilizing historic Jacquard Circular Lace machines, we create unique fabrics and 3D textile structures featuring zonally targeted performance properties. By seamlessly integrating design and fabrication into a single step, TEF Braids produces efficient, high-performance textiles that redefine sustainable, low-impact manufacturing and functional fabrics.

1. PROPOSAL TITLE: What is your succinct project title? (100 character limit)

Regenerative Braided Footwear: Hemp-Based Uppers Using TEF Braids and Biodegradable Composites

2. INDUSTRY CONTEXT: What need are you addressing, and how is it relevant to the New York sustainable textile industry? (1000 character limit)

The footwear industry faces urgent pressure to reduce its environmental impact, particularly in materials and manufacturing. Most footwear uppers rely on synthetic textiles or leather, which are resource-intensive and difficult to recycle. Our project addresses this need by introducing braided uppers made from New York-grown hemp and biodegradable thermoplastics—materials that are renewable, breathable, and compostable. Using TEF Braids technology, we can shape high-performance, low-waste textiles directly into ergonomic footwear forms. This innovation supports the New York sustainable textile ecosystem by strengthening regional hemp supply chains, introducing next-gen bio-based composites, and creating local manufacturing opportunities. It aligns with the state's goals to lead in regenerative fashion, reduce textile waste, and foster advanced textile R&D.

3. PROJECT SUMMARY: What are you proposing to do with a $10,000 NYFIC Grant? (1000 character limit)

With a $10,000 NYFIC Grant, we will prototype sustainable braided footwear uppers using New York-grown hemp blended with biodegradable thermoplastics. We will apply our technology to develop 3D-formed, breathable, and durable uppers that reduce reliance on leather and synthetics. The funding will support material sourcing, braiding trials, thermal shaping, and functional testing (fit, durability, breathability). We will produce and evaluate 3–5 footwear upper prototypes and collaborate with NY-based designers to explore design aesthetics and comfort. This work lays the foundation for regional manufacturing of regenerative footwear components and advances innovation in natural fiber composites. Results will be shared with industry and academic partners, positioning New York as a leader in sustainable textile and fashion technology.

Grant funds will support: This project promotes sustainable practices, local collaboration, and environmental stewardship—planting seeds of awareness and creativity in the next generation.

4. PROJECT WORKPLAN: What are your specific project tasks, milestones, and associated timeline? (4000 character limit)

Our proposed workplan will span 6 months and is structured around 3 main phases: Material Development, Prototype Creation & Testing, and Industry Integration & Knowledge Sharing. Each phase has defined tasks, milestones, and partners to ensure successful and timely execution of project goals.

Phase 1: Material Development (Months 1–2)

Objective:

- Source materials, optimize braiding inputs, and define processing parameters.

Tasks:

- Source and prepare hemp yarns grown in New York or nearby regional suppliers.

- Select and procure biodegradable thermoplastic filaments (e.g., PLA, PBS) compatible with hemp fibers and thermal shaping processes

- Conduct fiber compatibility testing and determine optimal hemp/thermoplastic ratios for braiding.

- Set up TEF Braids machine parameters for fiber tension, patterning, and throughput optimization.

Milestones:

- Successful production of small braided textile samples using hemp-thermoplastic blends

- Documentation of processing parameters and material behavior.

Phase 2: Prototype Creation & Testing (Months 3–5)

Objective:

- Develop 3D-shaped footwear uppers, perform performance testing, and evaluate ergonomic qualities.

Tasks:

- Produce 3–5 full-size braided uppers in various braid geometries (toe box, heel cup, side panels).

- Use heat forming techniques to thermally activate the biodegradable polymer matrix, locking the braided form into

ergonomic upper shapes. - Assess fit and durability through simulated wear tests, mechanical strength tests (tensile, flex, abrasion), and breathability evaluations.

- Collaborate with NY-based footwear designers to refine upper shapes for real-world comfort, aesthetic viability, and design

integration.

Milestones:

- Completion of at least 3 distinct functional braided footwear uppers.

- Documented performance results on mechanical and user comfort metrics.

- Designer feedback incorporated into revised braid shaping or assembly protocols.

Phase 3: Industry Integration & Knowledge Sharing (Month 6)

Objective:

- Prepare commercialization roadmap and share findings with the broader sustainable fashion ecosystem.

Tasks:

- Develop detailed technical documentation of braiding methods, material properties, and shaping techniques.

- Identify New York-based manufacturers or brands interested in piloting the technology in small-scale production.

- Create visual documentation (photos, videos, process diagrams) to communicate innovation clearly.

- Present results to relevant stakeholders, including NYS sustainable fashion groups, educational institutions, and potential investors or collaborators.

Milestones:

- Final project report and visual case study package.

- Preliminary partnership discussions with footwear manufacturers or sustainable fashion brands.

- Prepared roadmap for scaling and refinement in future funding phases.

5. PROJECT OUTCOMES: What are the expected outcomes from completion of this project? (1000 character limit)

This project will yield the first generation of fully shaped, functional braided footwear uppers made from New York-grown hemp and biodegradable thermoplastics. We expect to produce 3–5 prototype uppers that demonstrate durability, comfort, breathability, and aesthetic viability. Technical documentation and material performance data will support further development and commercialization. Outcomes also include stronger connections between local fiber growers, textile innovators, and footwear designers, helping to establish a regional supply chain for regenerative materials. This work will position New York as a leader in sustainable footwear innovation and lay the foundation for future scaling, brand collaborations, and expanded research into bio-based composites for fashion.

6. PROJECT IMPACT: How will the project outcomes impact your organization/company and New York State? (1000 character limit)

This project will enhance our organization's capabilities in sustainable material innovation and footwear design, positioning us as leaders in eco-friendly fashion solutions. By developing prototypes using New York-grown hemp and biodegradable thermoplastics, we aim to establish a scalable model for sustainable footwear production. This initiative will foster collaborations with local farmers, designers, and manufacturers, strengthening the state's sustainable textile supply chain. The project's success could lead to increased demand for New York agricultural products, job creation in the green manufacturing sector, and a reduction in environmental impact from traditional footwear materials. Ultimately, this aligns with New York State's goals of promoting sustainable fashion and supporting local economies.

7. PROJECT ALIGNMENT: How is your proposed project addressing NYFIC’s mission/vision? (1000 character limit)

Our project directly supports NYFIC’s mission to advance sustainable textile innovation by pioneering a regenerative, low-waste approach to footwear design. We are applying novel braiding and shaping technologies to hemp—a rapidly renewable, New York-grown fiber—combined with biodegradable thermoplastics to create high-performance, compostable footwear uppers. This approach exemplifies circular design principles, supports local fiber economies, and minimizes reliance on petrochemical-based synthetics. By building cross-sector collaboration between farmers, textile technologists, and fashion designers, our project fosters an innovation ecosystem aligned with NYFIC’s vision for a thriving, equitable, and sustainable New York fashion industry.

8. PROJECT TEAM: What are your relevant background/qualifications? Who is your team, and what are their relevant background/qualifications? (1500 character limit)

The project is led by Brad Jamison and Terri Jamison, co-founders of Tensengral and creators of TEF Braids. For over a decade the couple has been building on the heritage of lace as both structure and ornament, transforming jacquard circular lace braiding into a form of zero-waste, additive textile manufacturing that bridges design and engineering.

-

Brad Jamison brings decades of experience in engineering and sustainable systems. He developed the proprietary TEF Braids technique, informed by principles of tensegrity, which allows for seamless, sculptural, and highly functional fabric forms. His technical expertise drives the project's innovative production methods and scalable applications in circular fashion.

-

Terri Jamison leads creative direction, product development, and ecological storytelling. With a background in design, she has developed community-based projects that fuse local ecology, artisan techniques, and youth education. Terri will guide the visual identity of the hats, oversee dye development, and lead the creation of the storybook hangtags and educational website.

Budget

1. Materials, Supplies: $3,000

Description: Hemp fibers, biodegradable thermoplastic pellets/yarns, braiding filaments, footwear lasts, and shaping molds for prototyping.

2. Equipment: $0

Description: No major equipment purchases; existing braiding and heat-setting machines will be used.

3. Contractual Services: $2,500

Description: Compensation for a local footwear designer or technical consultant to assist with design refinement and ergonomic shaping.

4. Marketing: $500

Description: Development of a short case study video and visuals to communicate the innovation to partners, funders, and media.

5. Personnel: $3,000

Description: Support for lead project staff and technicians conducting braiding trials, shaping, and testing over the 6-month timeline.

6. Construction, Renovation, Site Work: $0

Description: Not applicable; no site renovation or construction needed.

7. Travel: $500

Description: Regional travel within New York State for in-person collaboration with fiber suppliers and potential manufacturing partners.

8. Other: $500

Description: Prototyping consumables (e.g., testing supplies, adhesives, labels) and digital tools for CAD/aesthetic visualization.

9. Total Amount Requested: $10,000

10. Please describe any matching funds or resources (e.g., in-kind) you have that are relevant to the proposed project.

We will contribute in-kind access to our TEF Braids equipment, workshop space, and previously developed tooling valued at approximately $7,500. RPI’s research collaborators may also contribute technical support and lab access for material testing.

"Regenerative" refers to a design and manufacturing approach that goes beyond sustainability by actively improving the environment, economy, and social systems it draws from.

- Using New York–grown hemp, a crop that restores soil health, requires minimal inputs, and sequesters carbon.

- Combined with biodegradable thermoplastics, the product can return safely to the earth at end-of-life.

- Supporting local fiber farmers, textile innovators, and designers to create a closed-loop, regional supply chain.

- Designing products with materials and processes that minimize waste, avoid fossil fuels, and allow for composting or recycling.

Regenerative Footwear has a forward-looking, holistic impact—not just making “less harmful” products, but ones that contribute positively to ecological and community resilience.