Programmable Circular Lace Braiding

Programmable braiding machines, although relatively unknown, have a crucial role in textile manufacturing beyond their traditional association with lace bands.

Research

In 2010 David Branscombe Ph.D of Auburn University, was one of the first to explore lace braiding technology in an academic setting in his manuscript New Directions in Braiding which provided a history and evolution of braiding, braiding machinery, and related engineering developments is provided with emphasis on the design, manufacture.

In 2018 David Branscombe Ph.D wrote another paper Lace Braiding Machines for Composite Preform Manufacture which evaluated the value of a modern lace Lace Braiding technology intricate three-dimensional textile structures suitable for lightweight composite materials that offer advantages such as near-net-shape production and tailored reinforcement in all three spatial directions, making them valuable for composite engineering.

Patents

In 2015 Brad Jamison of TEF Braids received a patent at the USPTO Patterned Plexus of Filaments, Method of Producing and Articles Containing Patterned Filaments US 20140377488 A1 relating to filament networks or a patterned plexus of filaments, such as, woven fabrics, and the articles that can be fabricated with filament networks,

such as, footwear, apparel, accessories, sporting goods, and equipment; more particularly, the present invention relates to multi-axial filament networks comprising linked and interwoven strands, which provide enhanced flexibility and endurance to the plexus of strands, and the articles that can be fabricated with the multi-axial filament networks, such as, footwear, apparel, accessories, sporting goods, and equipment, having enhanced performance, flexibility, structural

qualities, and endurance.

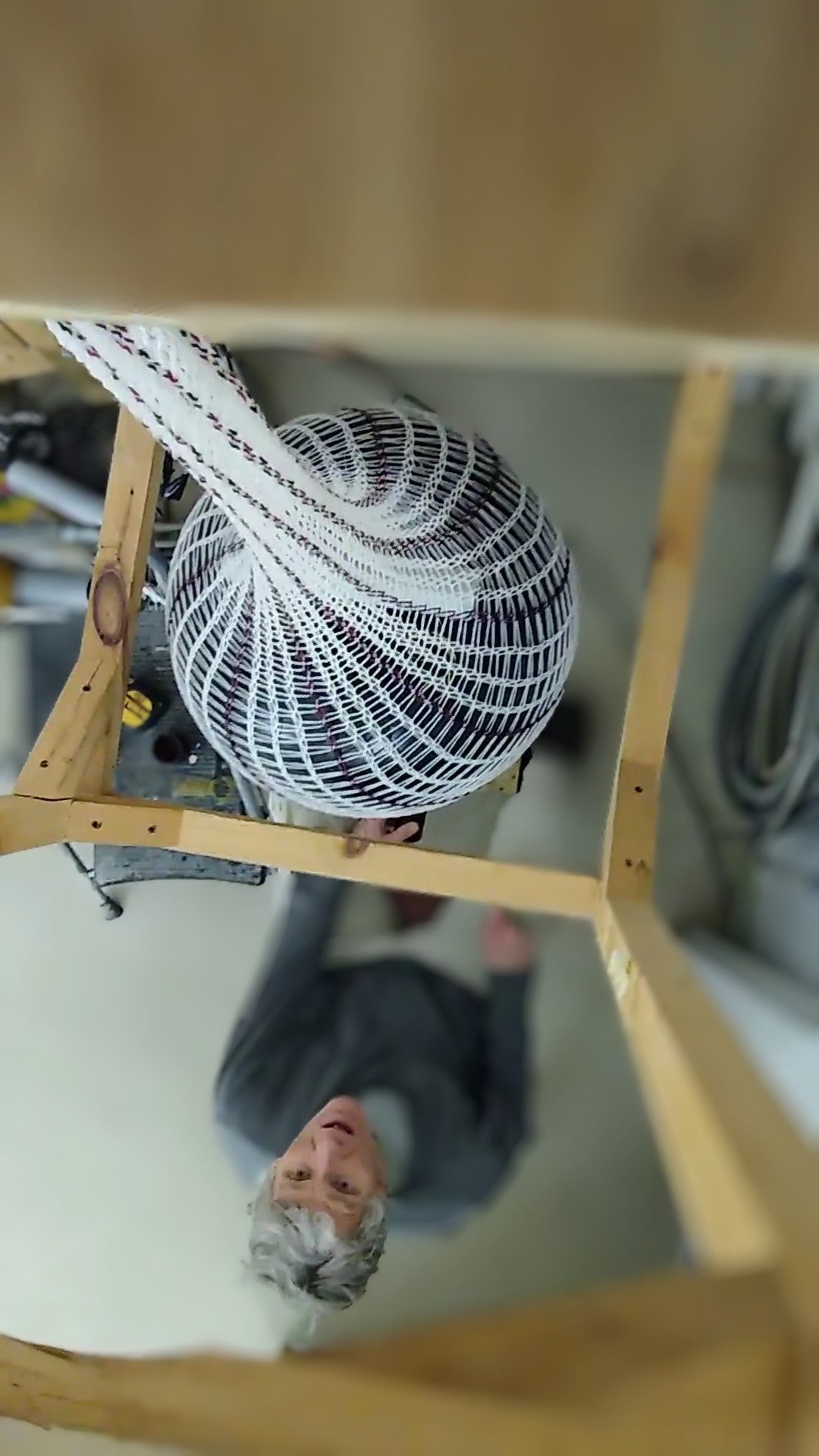

In 2017 Brad Jamison of TEF Braids received a second patent at the USPTO Plexus of Filaments with Linked Members which describes a plexus of filaments which is composed of paired filaments which travel extensively around one another to form a double helix structure exhibiting greater conformal and constrictive qualities in comparison to the prior art. Also disclosed is a method of producing filament structures for a variety of uses including composite structures, with enhanced structural properties, including tension displacement properties, for use in applications requiring conformal load distribution with minimal weight.

Innovation

We embody full circle innovation with our new designs, materials and zero waste, efficient manufacturing process, that address performance and sustainability issues using only unified filament networks.